A long time viewer of my Bilibili channel contacted me to do a restoration of his Korg Triton.

Summary

The Korg Triton is a synthesizer and sampler workstation available from 1999. It has a resistive touchscreen. The unit was sent to me and was in working condition.

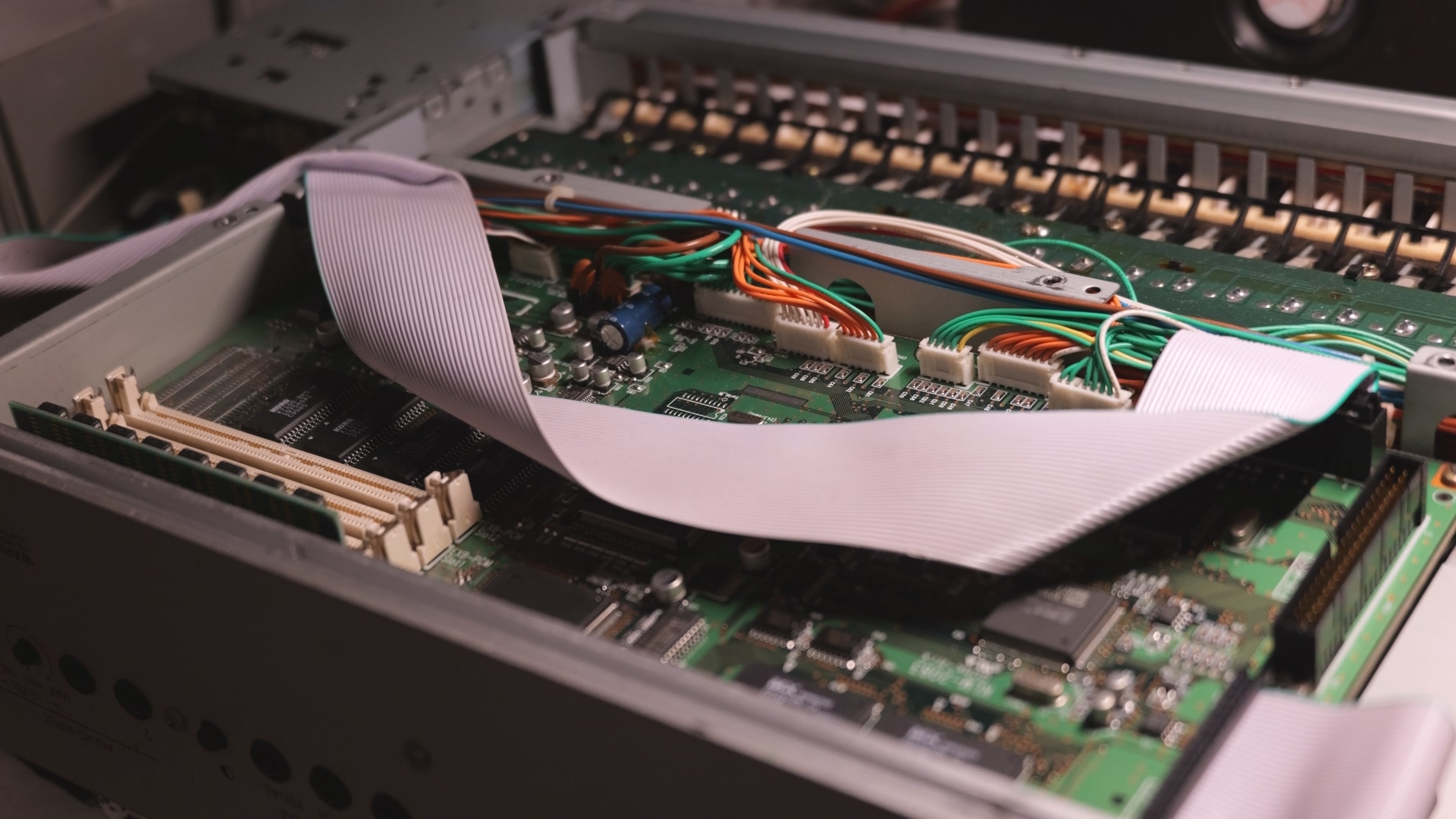

Inspection

The owner complained about low volume of the analog input, control buttons not working well, joystick issue and an encoder that’s jumping around. Upon arrival I did a functional test using the built-in test mode and found no problem with analog input or output, but all other issues are there and also the touch controller need adjustment. In addition, one of the plastic side cover is cracked. Some of the molded-in boss were broken.

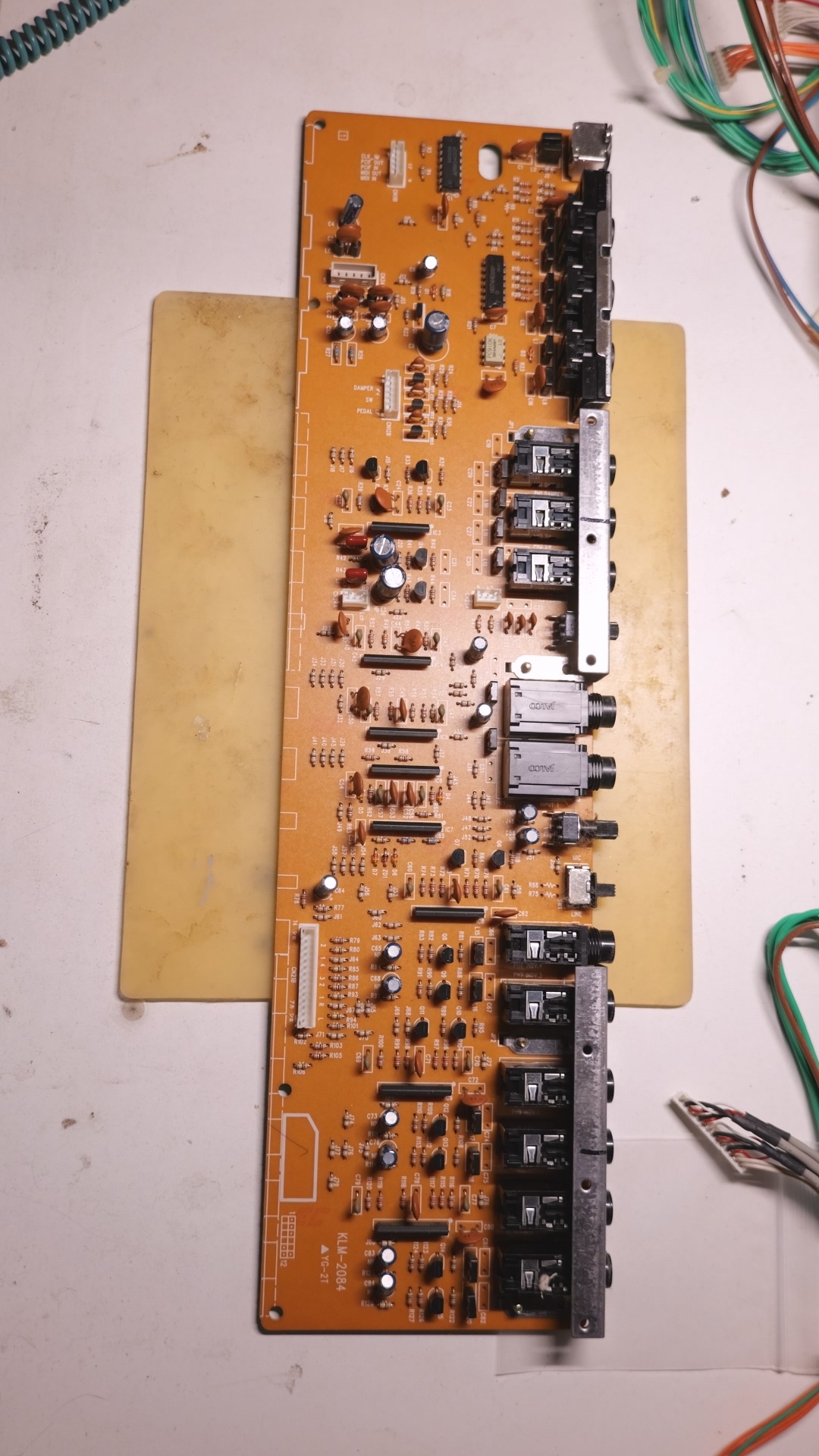

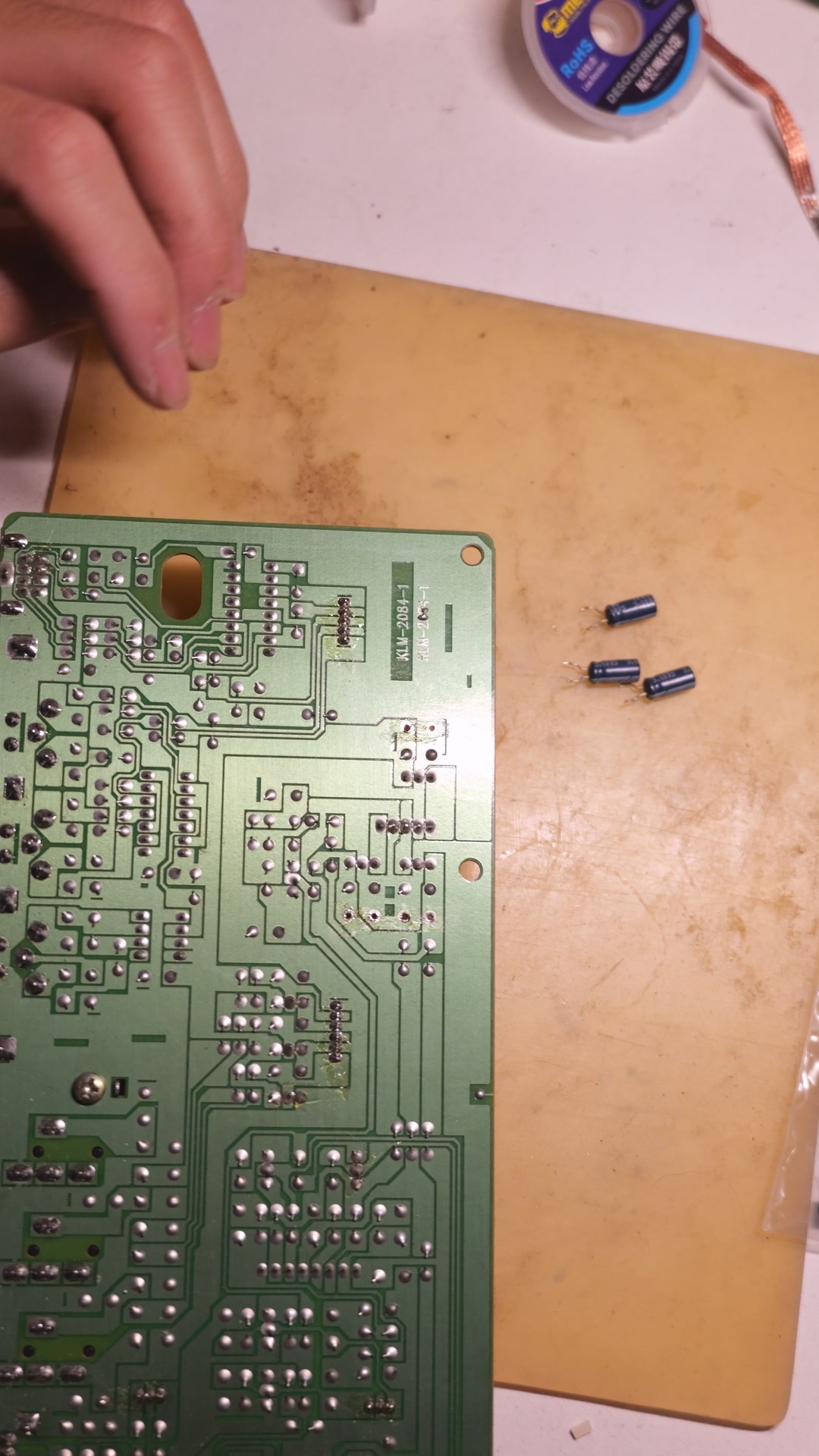

Checking Capacitors

Since the owner complained about the analog part, I removed some capacitors from each section of the board and tested them with LCR meter, including analog in, analog out, power capacitors on the main board and PSU. All of those tested fine so I chose to not replace any of them.

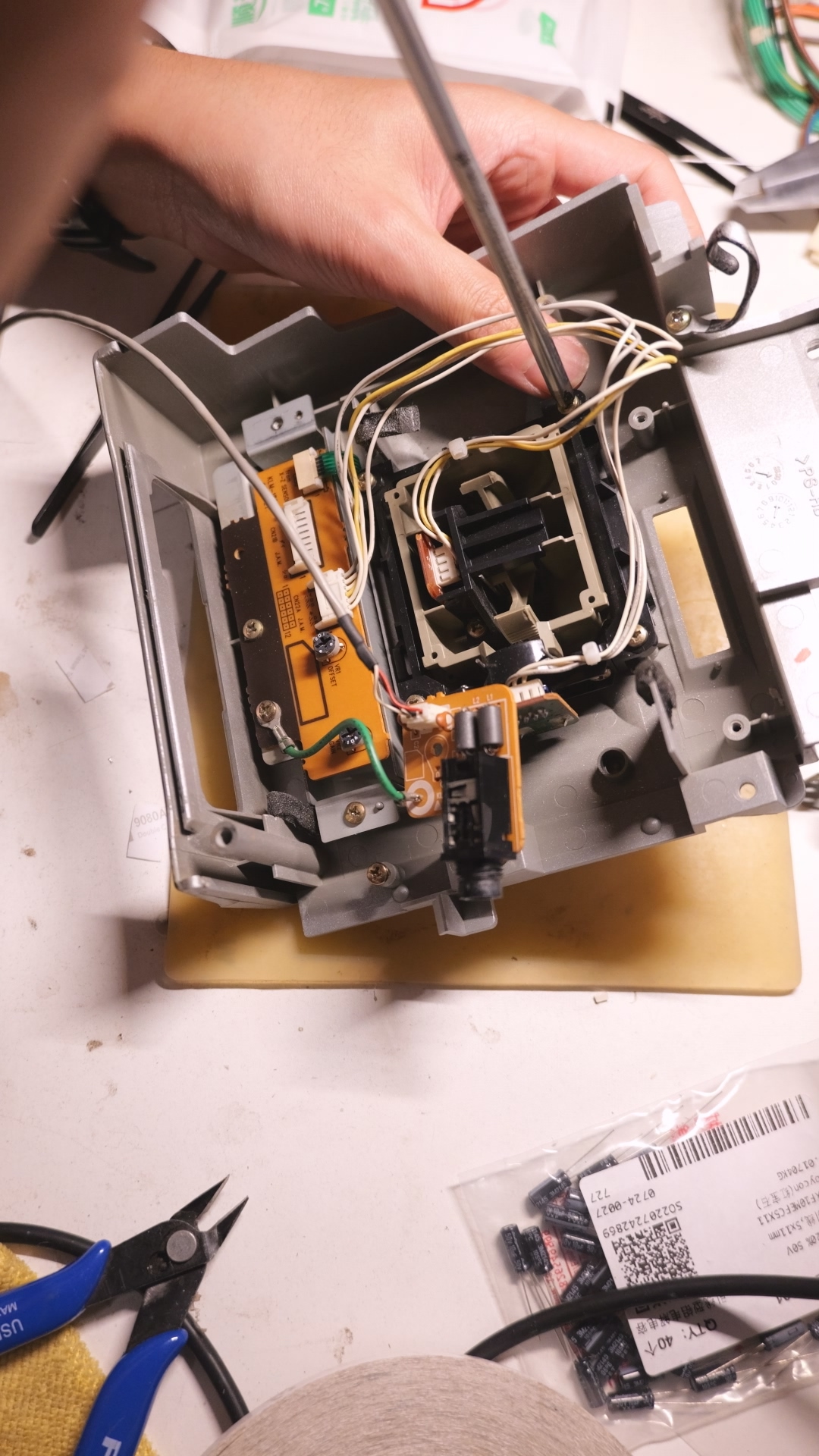

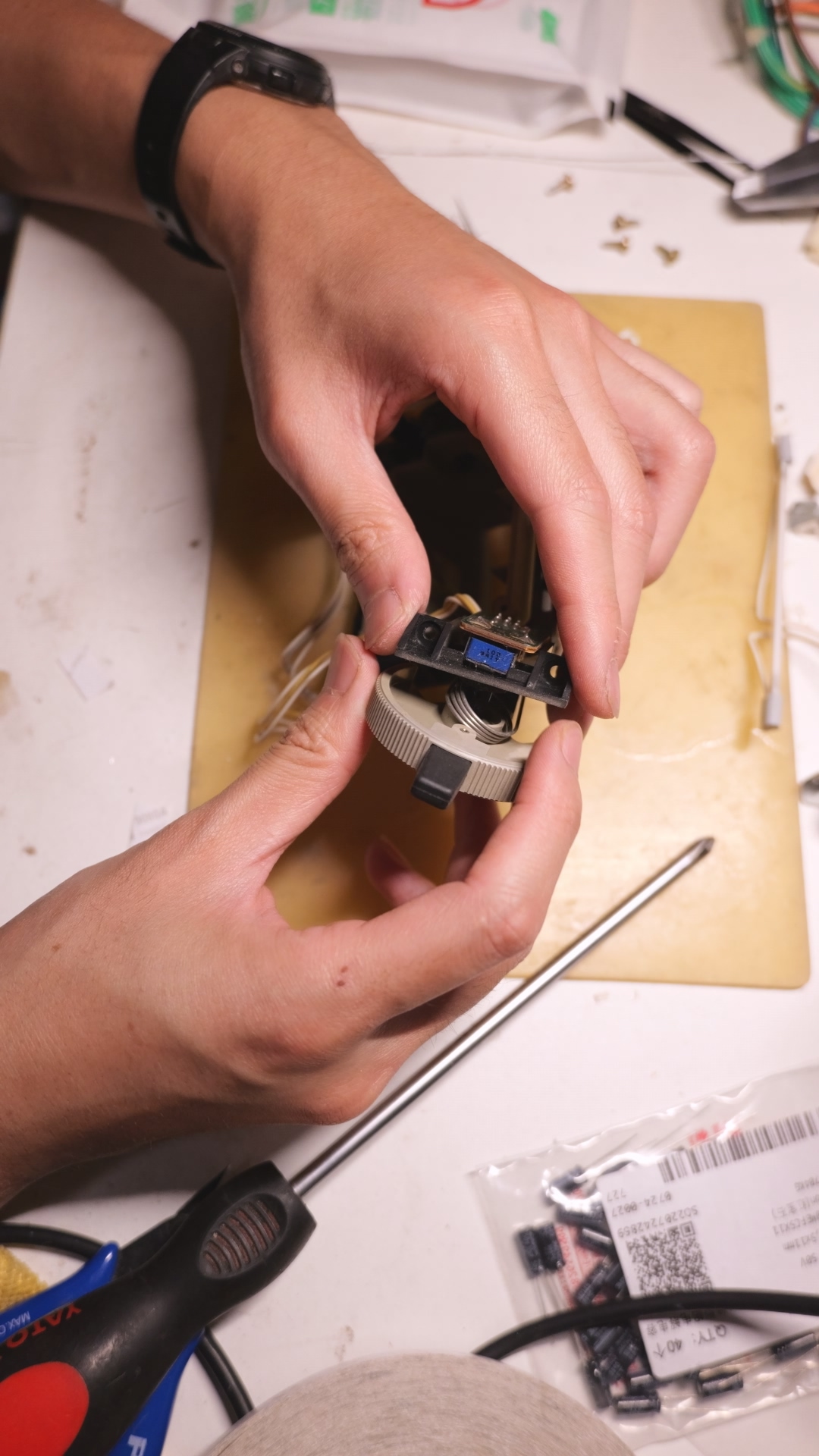

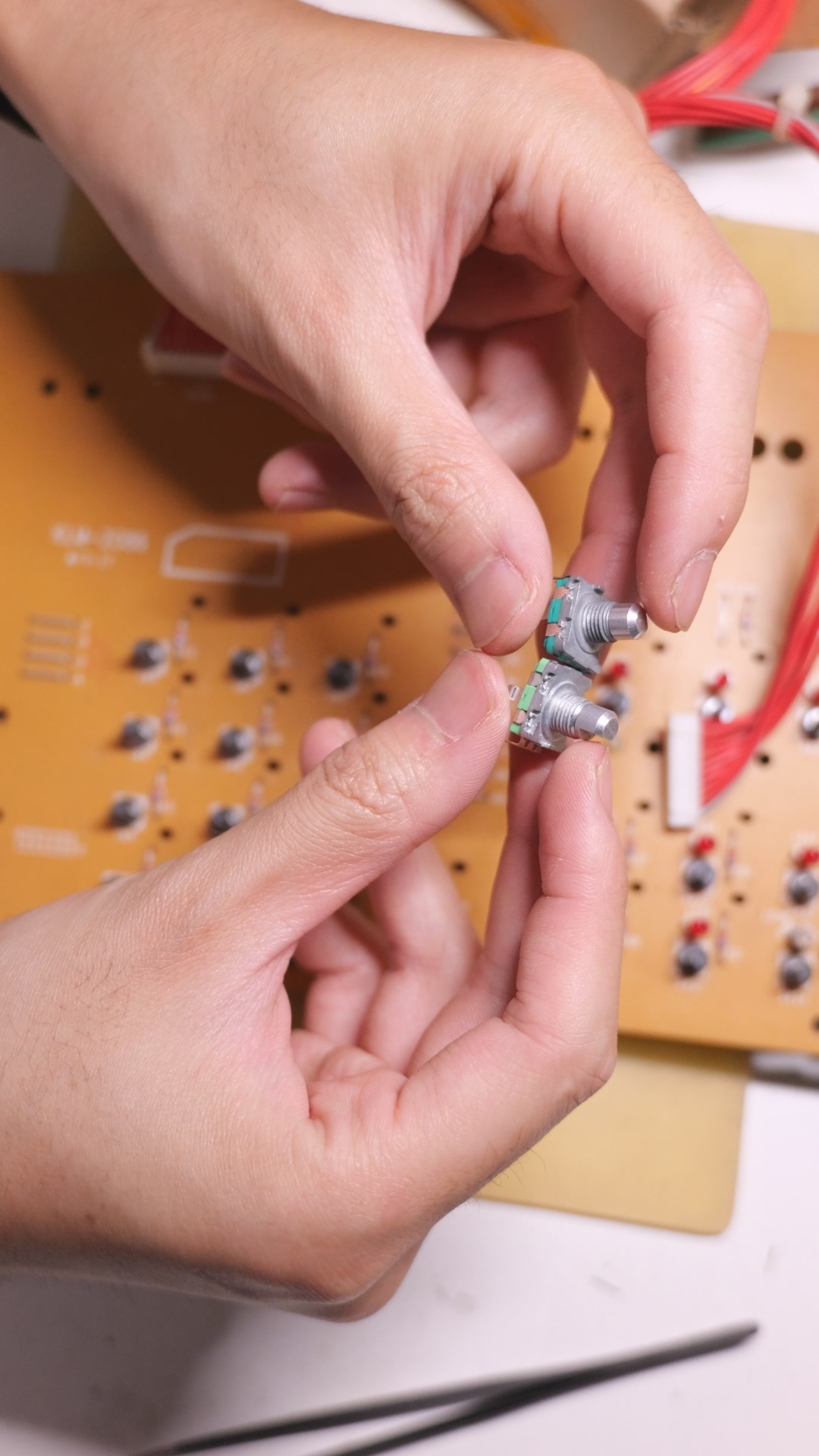

Repairing Joystick

The joystick has a lot of play on both X and Y axis and will stuck when moved to the right. The nut of the potentiometers are all loose which caused this issue. I put thread-lock glue and tightened the nuts. I also put some glue on the shaft so that the handle won’t slide on the shaft.

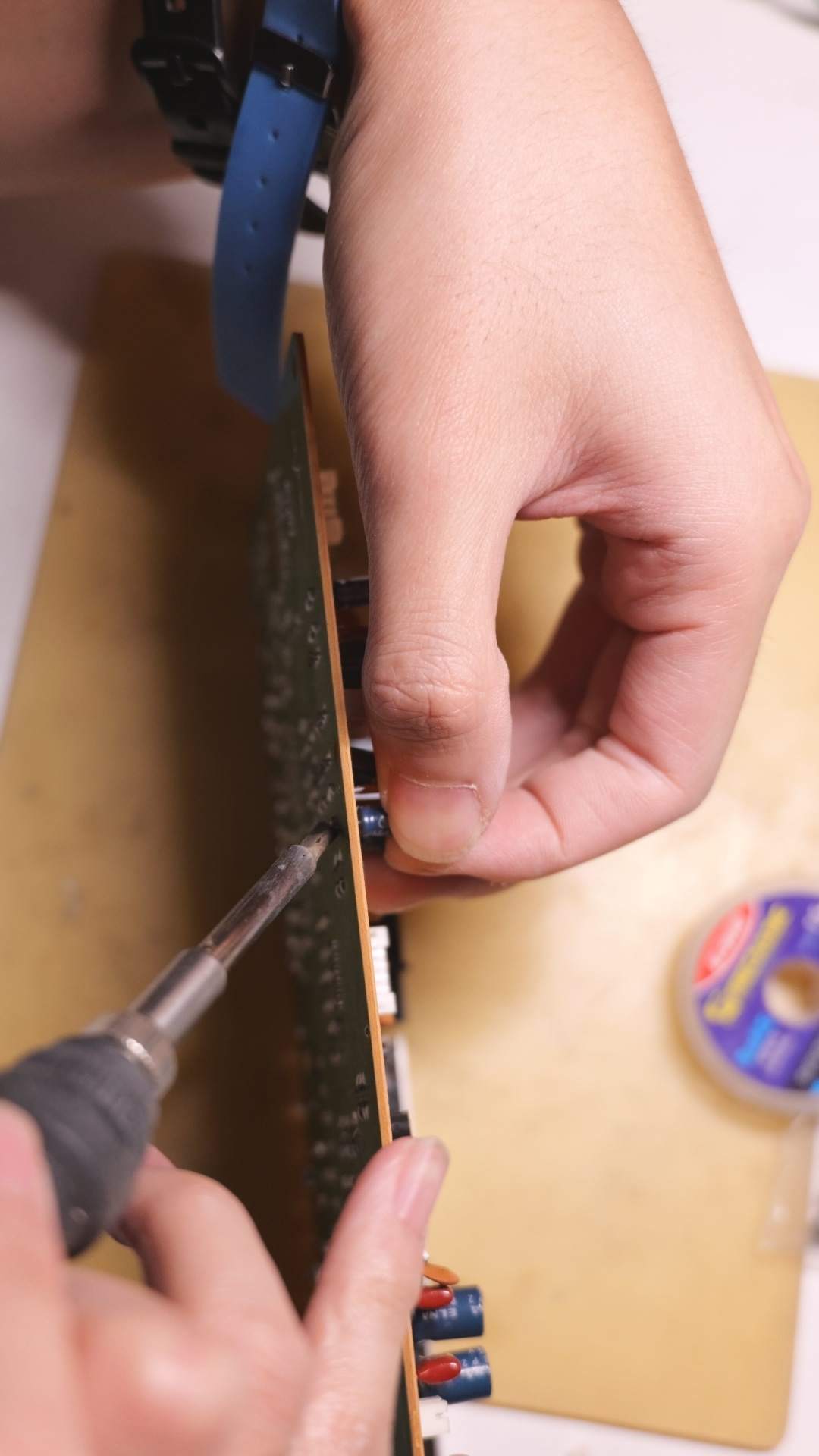

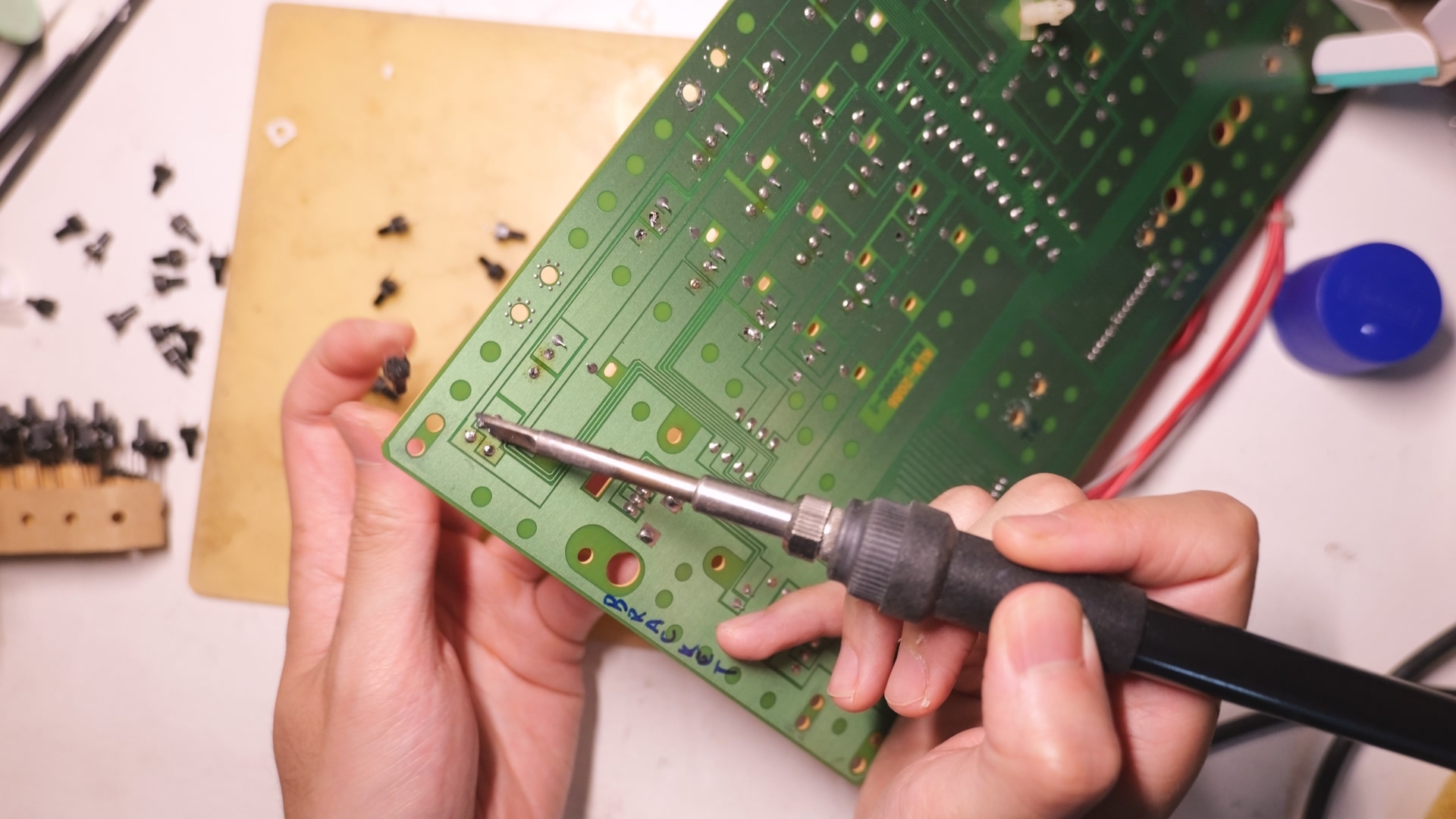

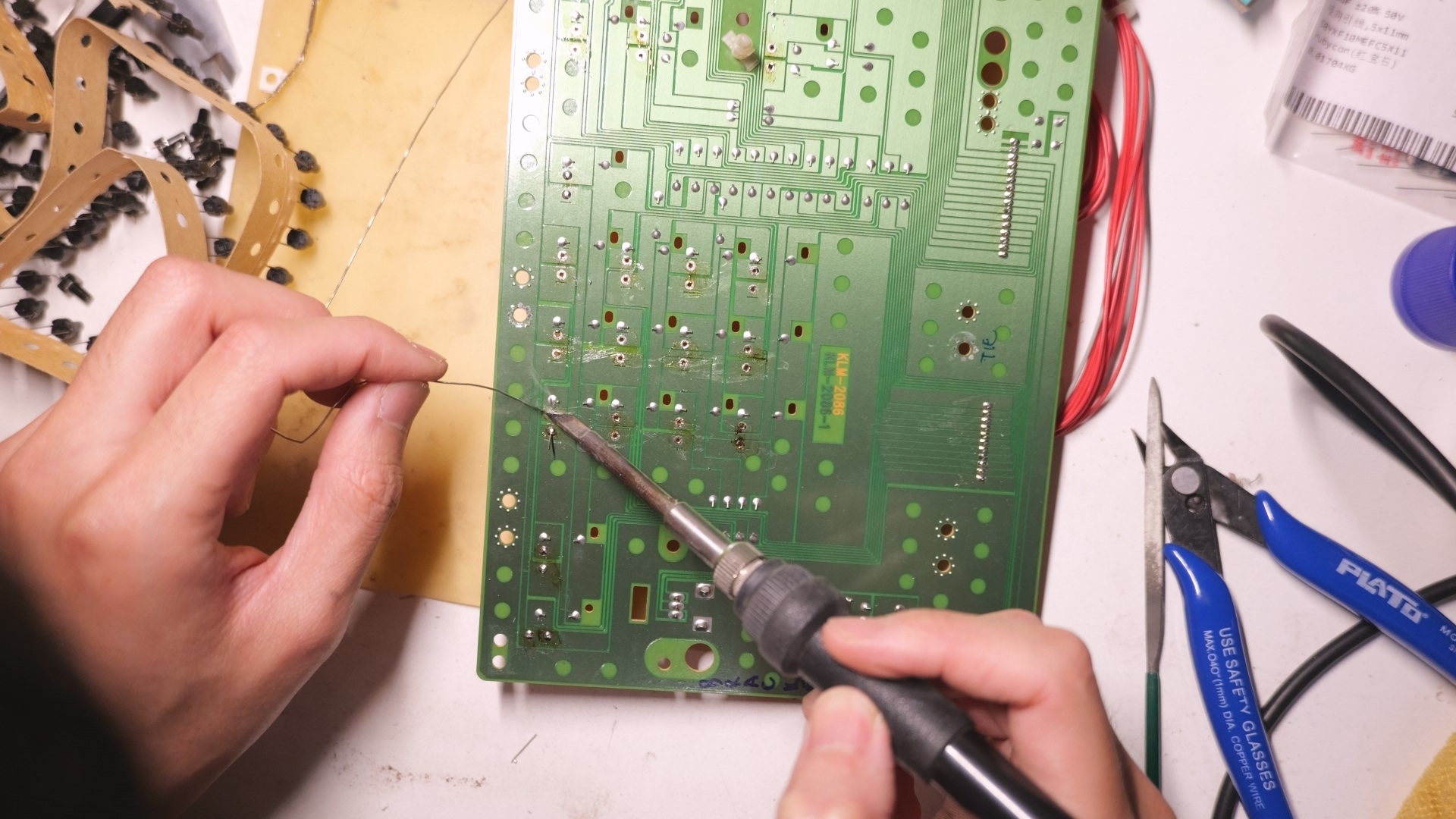

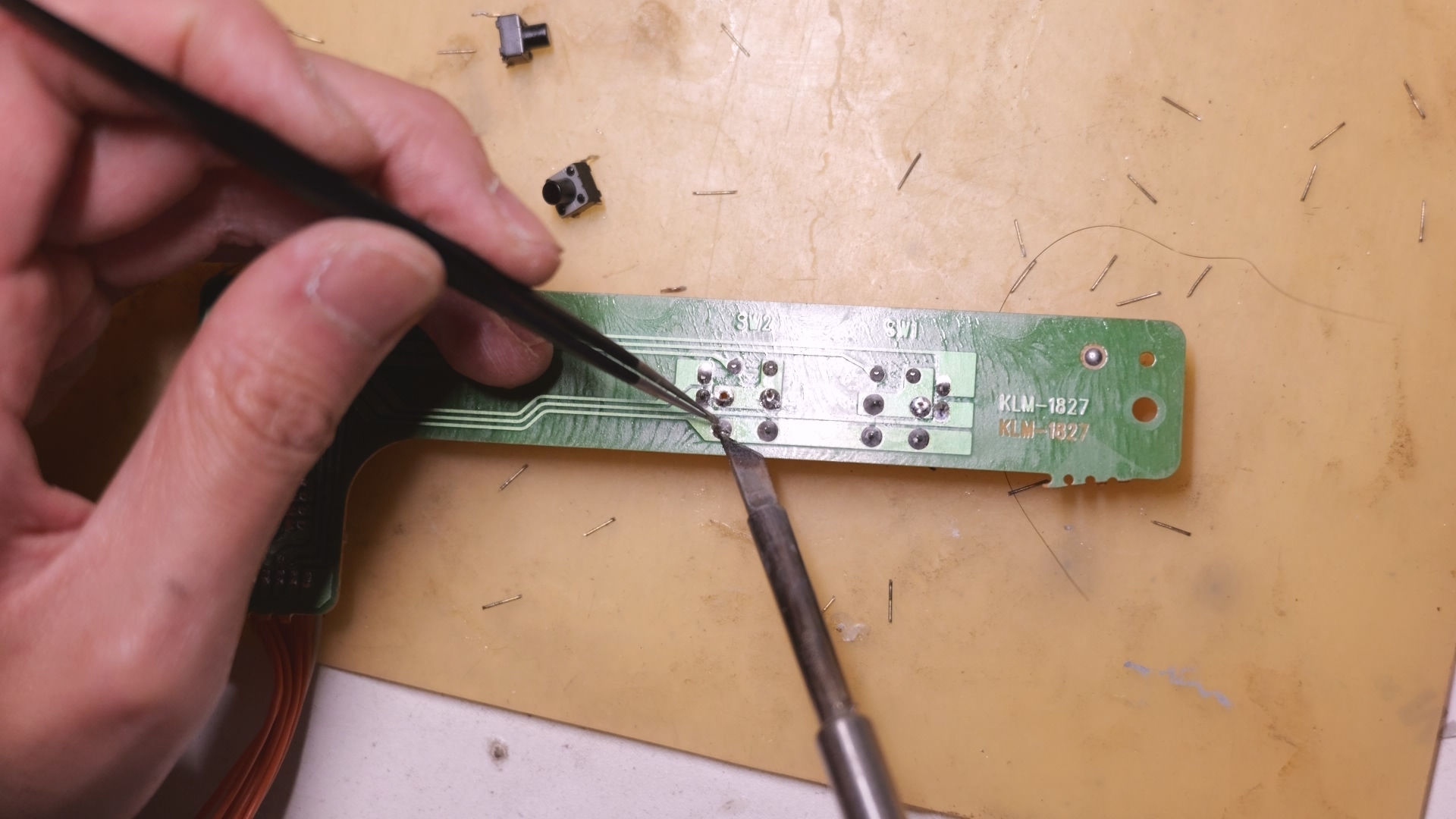

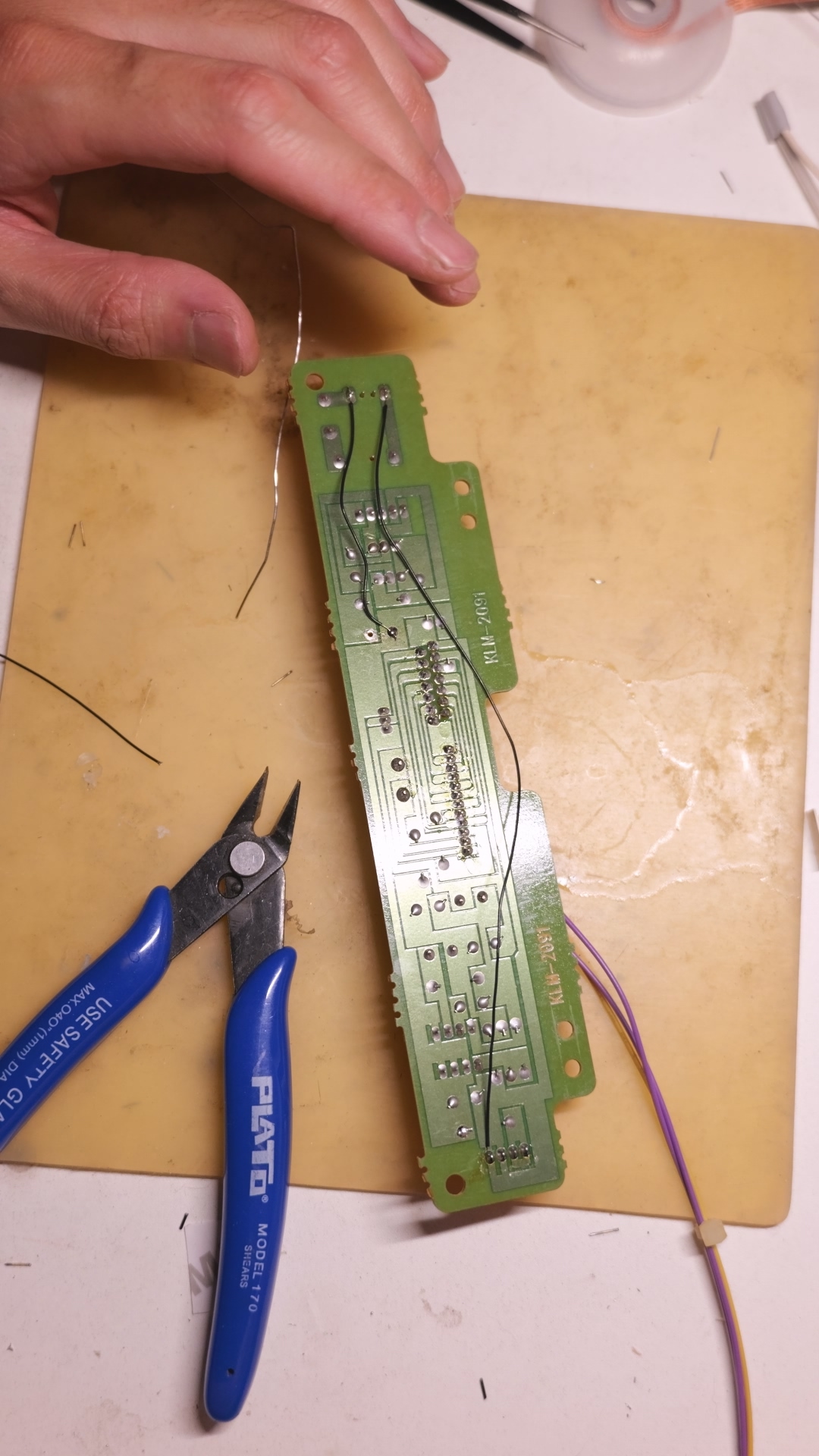

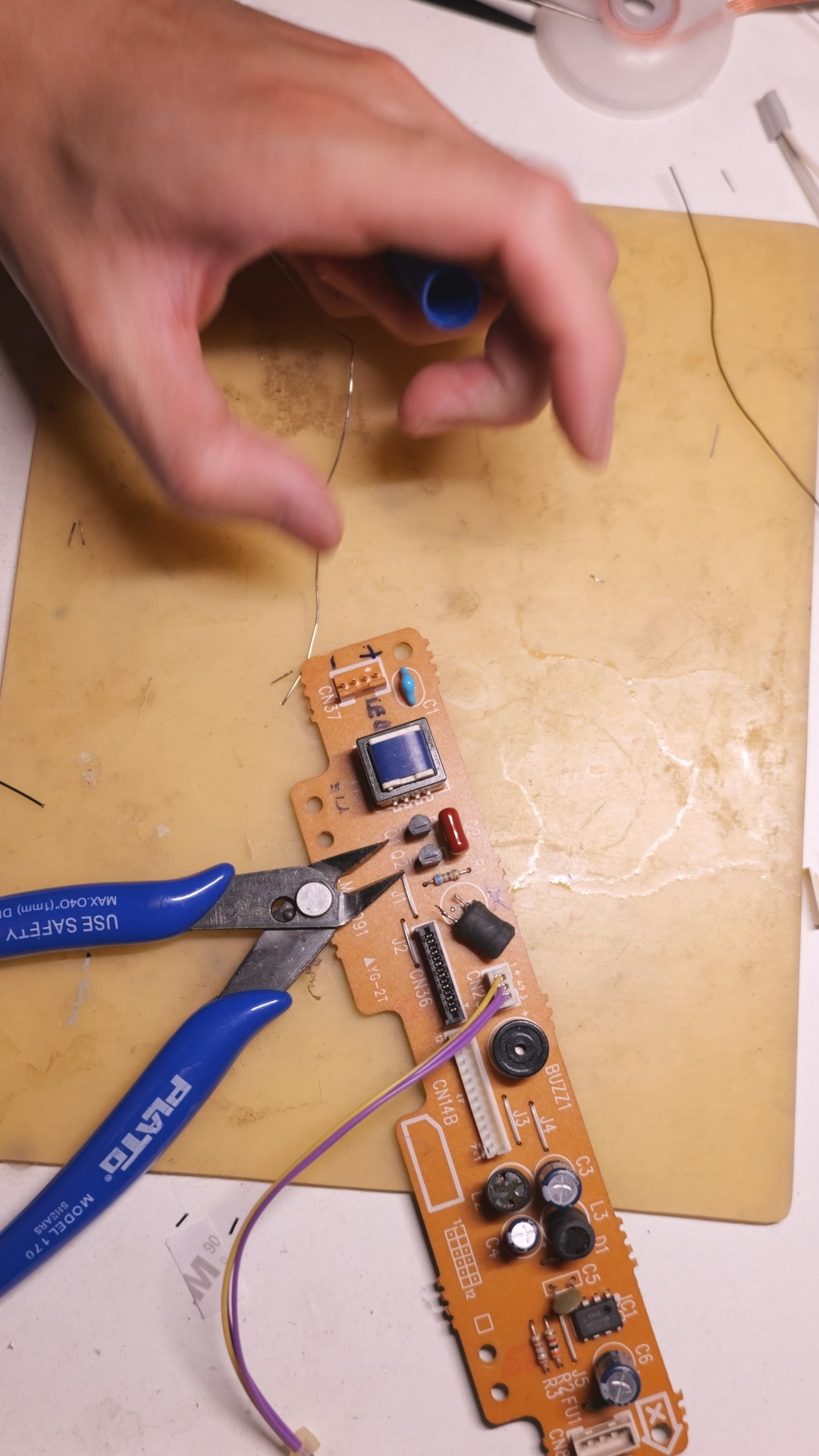

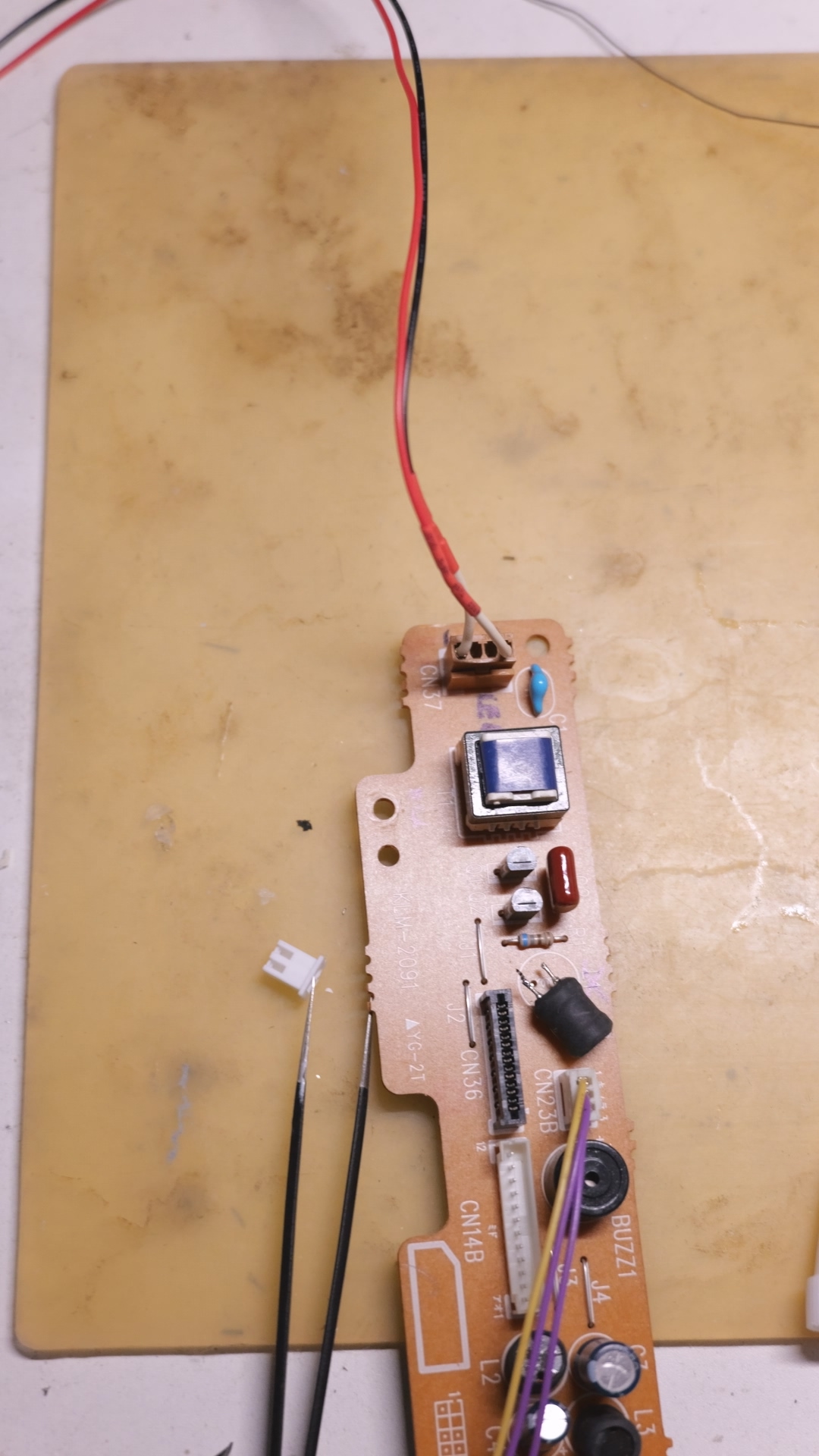

Replacing the keys

This is relatively simple and straightforward. Just remove all tactile switches and replace with new ones. I couldn’t fine exact same button so I replaced with ones that has a little bit higher actuation force. Most of the buttons are 2-pin and is not easy to source, while the assignable buttons are standard 4-pin.

Replacing the Encoder

Info regarding Korg encoders from SynD, thank you for the info:

From what I can see in Triton service manual, rotary encoder pot is model EC16B242041SA, Korg part code 500370004500, alternate part code 510370520001, the same as used for every Triton model, M3, Trinity, D16 & D3200 recorders, Electribe EMX1, i2/i3/i4, PA80, more. They’re discontinued by Korg, but may still be available online, plus alternates are available.

Synth-Parts.com uses an alternate: “Product number: ENTA160-2415A_1KO

Brand: Taiwan Alpha Electronic Co., LTD.” (*NOTE: “Thread of this encoder is 2 mm longer than the thread of the Original encoder…”)

https://www.synth-parts.com/en/products/encoder/5215/encoder-16-mm-for-korg

The encoder is still acting up after blasting with contact cleaner. I bought a new one but it’s not the same spec which resulted in 2 pulses with one detent of rotation. I couldn’t find anything to match the original spec and it was too expensive to custom order, this was the best I can do which I’m not satisfied with.

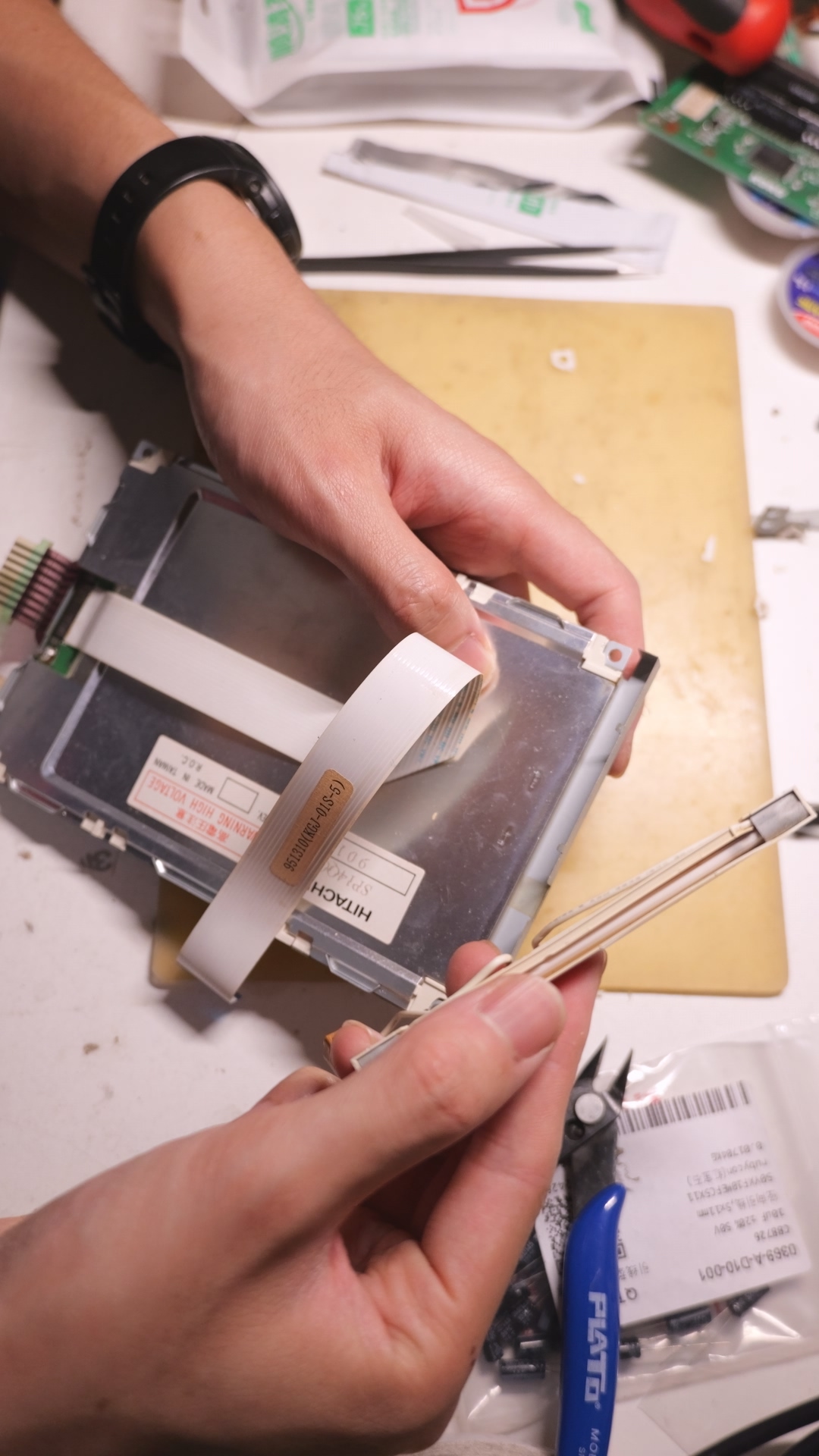

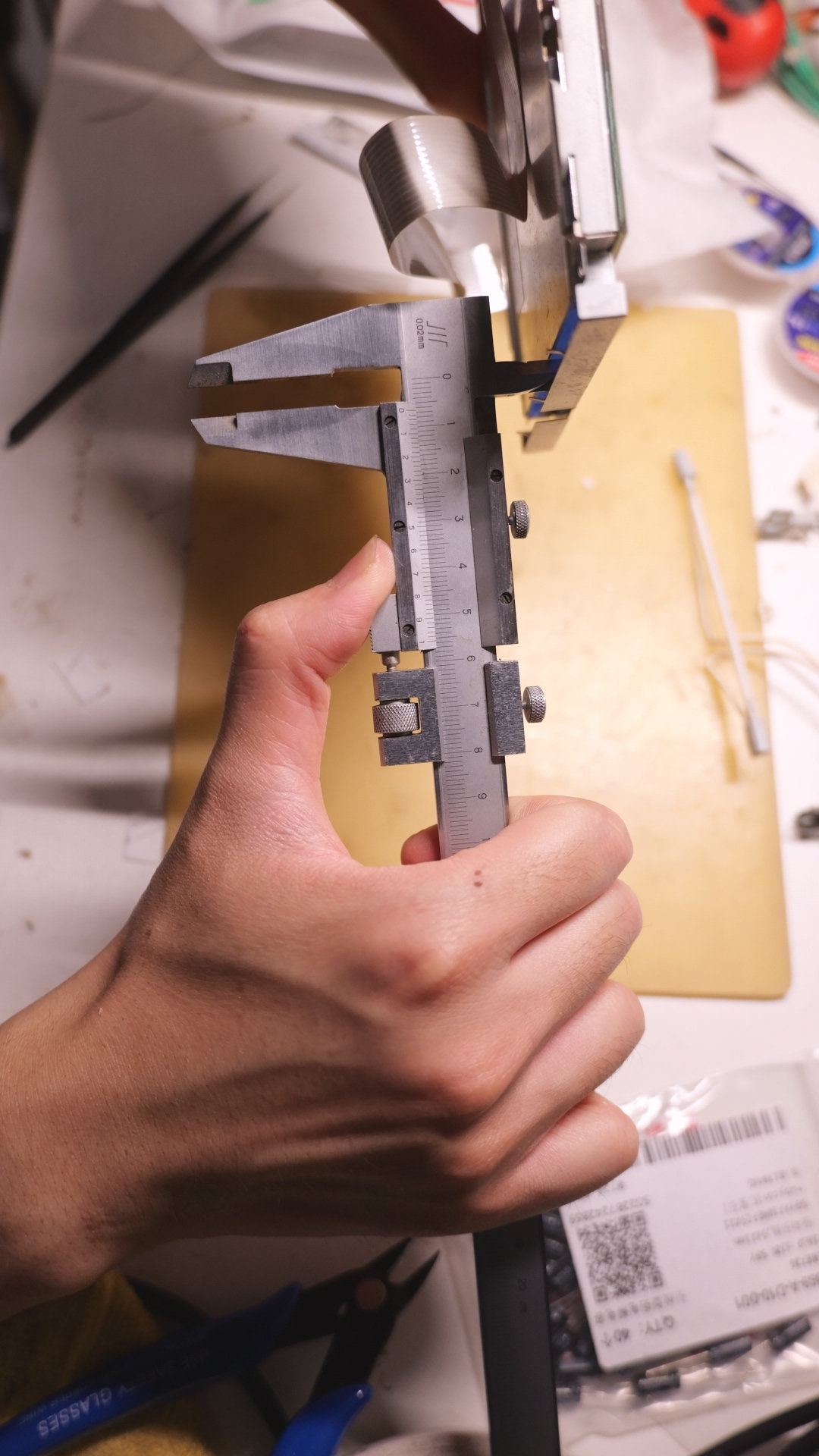

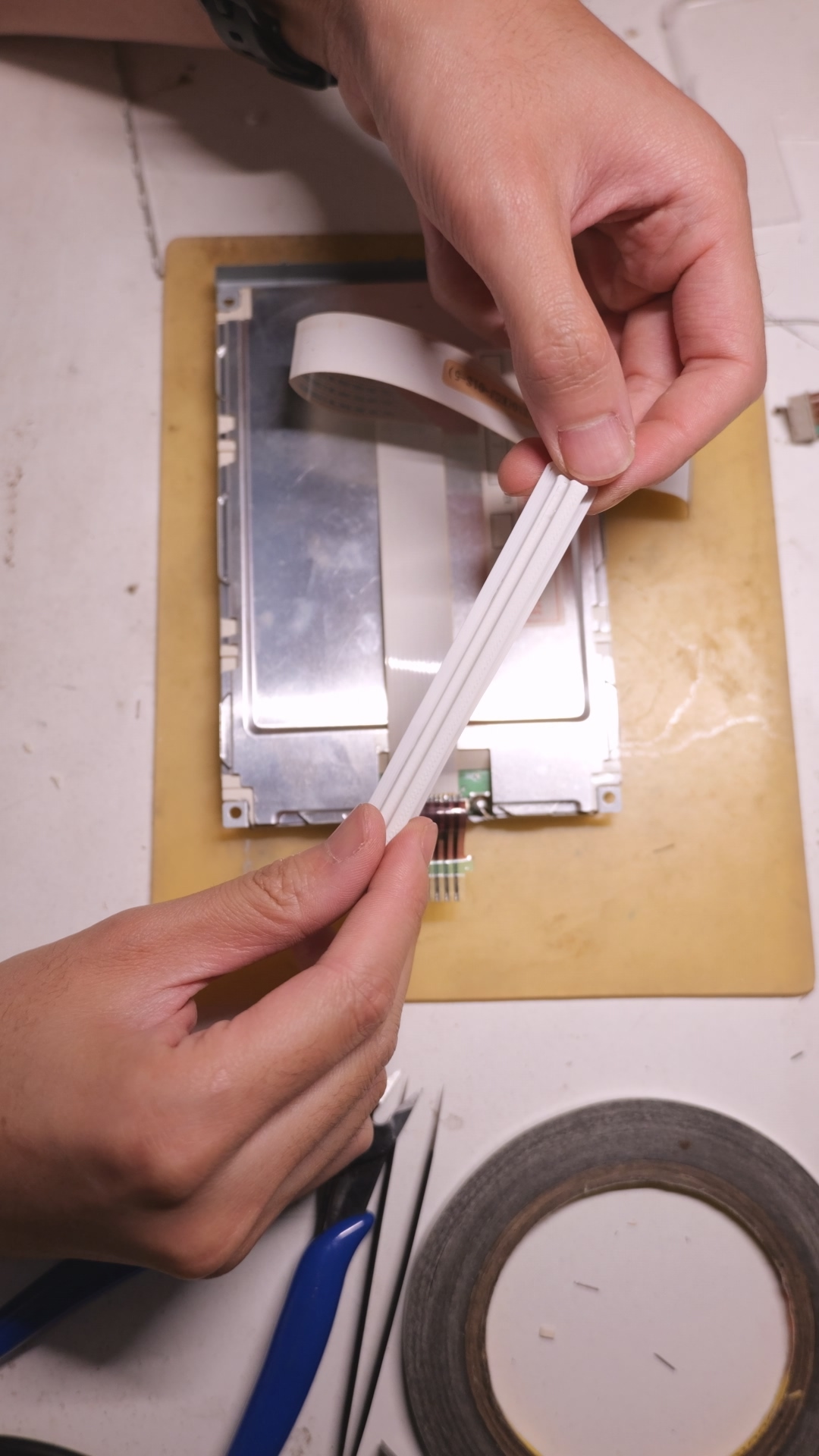

Modify Backlight

The original backlight of the LCD screen is CCFL which has faded over time. I replaced it with LED backlight stripes for industrial control screen. The original mounting bracket for the CCFL is not reusable and it also shattered while I tried removing it. So I 3D printed a new bracket to accommodate the LED stripe.

It’s also necessary to modify the backlight circuit. I removed the inductor through which the step-up circuit is powered, and put 5V on the backlight connector.

Replacing FDD with USB FDD

Similar to what I have done with the XP-80, I replaced the FDD with a USB emulator (GOTEK). It was flashed with flashfloppy firmware as well. You should be able to use the free version of HxC, which has more functionality.

Assembling and testing

I used superglue and baking soda to repair the crack on the side cover. I fixed some of the broken boss on the plastic parts. I did thorough cleaning of the surface. I upgraded the synth firmware to latest version .

Before shipping I also recorded the full demo set. You can listen to it at DemoDB: https://demodb.org/korg/triton/triton_classic (English and Japanese UI are available with menu at top right corner)

Also on my Bilibili: https://www.bilibili.com/video/BV12uyAYzEUg

Hi,

I’ve just come into possession of one of these with a damaged screen. Is it possible to get it repaired?

Hi:

The LCD itself can’t be repaired if it’s shattered. You can buy new LCD modules from China, you can find them on AliExpress or Taobao.

Hello Bro, can I have or get your WhatsApp number please, I need your help.

What kind of assistance do you need?

Yes, the unavailability of branded, quality parts sure there sounds frustrating.

I’m not familiar with superglue and wires technique to install/adapt SMD switches, but I have two Roland modules and a keyboard, all very nice models, that all need recapping with SMD caps because crackling audio output, and I’ve no experience in that whatsoever…

Good article re CCFL, I didn’t see much about its brightness “curve”. (Interesting to see Analog Devices owns “Analog.com” domain!)

Yes, I’d imagine modern LEDs last longer, but if you replace CCFL in a Triton now and it lasts another 25 years, you have to wonder if the rest of the synth will be viable at that 50-year point, anyway! (I hope it is, indeed!)

Best,

SynD

sir good morning i have korg triton classic i bye it used belt in usb no floppydisk

i tray to update framware from 1.0.6 to 2.5.3 i download from korg site soft ware

i put in flash usb when i press in korg triton ENTER + LOCATE it tray to update

it give me error when i sholdown my triton and open it not work it give me white screen only no light only white light and usb light only no baddy can fix it in emirates uae

can u help me plz i need one good tichnain my number 00971569499999 whats app

thanks sir

I don’t know the exact state of your Triton with blank boot screen since your aborted OS update attempt, but if your Gotek USB floppy emulator device displays “000” when powered in the Triton, I’d recommend uninstalling the Gotek in order to flash it with free HxC firmware, which will enable you to update the Triton-OS properly from USB flashdrive using the instructions in my article https://hxc2001.com/floppy/forum/viewtopic.php?t=4504

(If the Gotek instead now shows “F-F” when powered, then you can flash it to HxC while it remains installed in Triton, or if it says “hXc” then you already have HxC on it.)

I believe the Triton has a very small “bootstrap” ROM (8kB) that will still allow it to enter the OS update mode with [ENTER] +[LOCATE] on power up, despite your blank display now, so you can therefore still hopefully reinstall the OS and get it working again.

Best of luck.

I should CLARIFY: When checking which firmware type your Gotek now has installed, REMOVE ANY INSERTED USB FLASHDRIVE, then see whether the Gotek display shows “000” or “F-F” or “hXc” when powered.

Hi Conner,

Thanks for the useful and detailed overview of your Triton repairs.

A couple of questions and comments:

1) I think the tact switches fail on many keyboards earlier than they could because most all manufacturers use higher actuation force switches – which are necessarily rated for a shorter life. I also think this makes the button presses feel and sound “cheaper”, with a high pitched “click” and sometimes sound of hollow plastic button resonating.

The reason these higher-force switches are used on keyboard models is the orientation of a keyboard’s front panel is thought to lend itself to stronger, weightier presses, since the user is above it pressing down. Maybe the manufacturer’s are concerned with preventing users from stray, inadvertent presses interfering with operation. I think it’s bad design practice.

Contrast with most rack units where the front panel is vertical and perpendicular to the user’s press, so manufacturers use lower-actuation switches. Result: rack unit switches last longer, feel better, make less sound when pressed and are just more solid.

The Triton-Rack is a good example; switches don’t fail as frequently as the keyboard counterpart, plus feel great. Kurzweil used the same lower-force switches on both its otiginal K2000 keyboard and the K2000R rack, and the switches are quiet and last. Compared to the much pricier later K2500 model keyboards shifting to high-actuation switches that more quickly fail, versus the K2500R rack version that continued with same switches as K2000/K2000R. The buttons on my Ensoniq SQ-80 (ca. 1987) still all work and feel precise, quietly damped, and solid – same thing – because Ensoniq wisely used low-actuation switches.

With all this in mind, I will always try lower-actuation force tact switches for replacements on my keyboards (I’ve got a few that have a number of failing switches) especially if I’m changing all switches together.

2) From what I can see in Triton service manual, rotary encoder pot is model EC16B242041SA, Korg part code 500370004500, alternate part code 510370520001, the same as used for every Triton model, M3, Trinity, D16 & D3200 recorders, Electribe EMX1, i2/i3/i4, PA80, more. They’re discontinued by Korg, but may still be available online, plus alternates are available.

Synth-Parts.com uses an alternate: “Product number: ENTA160-2415A_1KO

Brand: Taiwan Alpha Electronic Co., LTD.” (*NOTE: “Thread of this encoder is 2 mm longer than the thread of the Original encoder…”)

https://www.synth-parts.com/en/products/encoder/5215/encoder-16-mm-for-korg

3) Re LCD backlight, from your experience, can you not change backlight without destroying its bracket?

Also, why modify to an LED backlight when a replacement original type CCFL bulb is both very bright and very long-life, and the bulb is readily available inexpensively?

4) Regarding Gotek USB floppy emulator, for Triton I strongly recommend flashing Gotek with free HxC firmware, and further using HxC’s Imageless Mode so that a properly prepared USB flashdrive becomes directly/natively accessible in Win/MacOS, without any additional proprietary diskimage formats and management software necessary whatsoever. Plus, HxC Gotek in a Triton offers benefit of limited compatibility with its large “superformatted” Imageless Mode floppydisk-partitions of 4MB to 7MB (or more), useful for sample loading from Gotek and eliminating or reducing disk-partition changes on Gotek. Finally, HxC facilitates upgrading Triton OS from a USB flashdrive, great for a new owner of an older-OS Triton who doesn’t have an external USB floppy drive and/or floppies to write OS floppy disks for the upgrade.

I wrote a detailed post/article about this at HxC official forum at:

https://hxc2001.com/floppy/forum/viewtopic.php?t=4504

Best,

SynD

Hi SynD:

Thank you for your elaborate comment.

For 1: Yes I think the higher actuation force is for preventing inadvertent operation. For replacement I always try to maintain original specification, when the customer has not given any instructions regarding this.

The priority of choosing replacement part for me is usually brand first(Alps->Panasonic->other), then specification(original actuation force->lower force->higher force). The part that have the specific brand and actuation force combination I want may not be available here in China, and it may or may not be feasible to place order from overseas, so sometimes I have to substitute with higher actuation force switches.

The favorite type of tact switch is the automotive Alps SKPM series. They have the best feel IMO. However it’s not possible to use those as replacements.

For 2: I was aware of those alternate parts at that time but I couldn’t get them. The customer does not agree to the price on synth-parts and if I order from the manufacturer there is MOQ which I cannot satisfy. So I used something that has similar specification, which unfortunately didn’t work out.

I’ll put the info you provided into the main post. I think the ultimate solution for these hard-to-get encoders would be to make a small PCB and adapt some readily available encoders to the footprint.

For 3: It will depend on the situation. The one that I repaired is very brittle, possibly due to the UV light from the CCFL bulb. So you may be able to change it without damaging the bracket.

Regarding CCFL vs LED I think it’s up to personal choice. The reason for LED backlight here is 1) it does not age, 2) it’s cheaper to order and I can order just 1 LED strip instead of at least 10 CCFL bulb at a time, and 3) the inverter can be deleted to reduce energy consumption, audible noise, and electrical noise coupling into audio output.

For 4: Thank you for the suggestion. I have been aware of HxC since a few years back. At that time it cost $10 per flash and the Artery AT32 powered Goteks were not supported. It seems now I should be able to use HxC!

Regards,

Connor

Hi again, Connor,

Just realized you replied, was expecting to get email notification, but glad I now checked tab of this page I left open in browser!

Yes, understand you want good quality tact switch replacement and can best trust a name-brand like Alps, Panasonic; I agree. It seems that lower actuation force ALWAYS equates to longer life (switches are rated for number of presses) AND, in practice on a synth, easier, more efficient, and more aesthetically pleasing feel/sound, so it’s clearly a win-win in using lower actuation force ones in my estimation. I have yet to try it, so can’t speak from absolute experience. I’d imagine any amount lower actuation force will convey some benefit, and there may be a point where the force rating is too low.

I just realized I can check data sheets of OEM switches used in keyboard synths vs their rack counterparts (e.g. Triton Classic vs Triton-Rack, of which I happen to own both) to directly compare OEM actuation force and life (MTBF or presses).

Those Alps SKPM sound nice; they don’t produce in a type compatible with most synths?

I don’t own a ton of different rack gear, but nicest switches I have are on JD-990 (likely identical to JV2080, and possibly JV1080 and others of era), pretty closely followed by Triton-Rack. (Can’t compare to Kurz K2000R since those still stored away remotely soon after I purchased a couple years ago, sadly.) I prefer samller buttons with less “travel” but TG77 have larger ones that pivot slightly yet feel solid, XV5080’s not quite as nice as JD990.

There must be other suppliers of encoders compatible with Triton, etc., doubt it’s too specialized or esoteric, but would take trial and error to identify other replacements.

Understand you have to work with what’s available locally (but I’d expect that to be quite extensive if you’re in /near mainland China).

Interesting theory re UV light from CCFL bulb deteriorating LCD bracket. I tried researching quickly re UV light emitted by CCFL, and information was a bit sparse, but one site stated in comparing CCFL vs. UV lights: “[CCFL] work by producing UV light that excites phosphors inside the tube to create visible light. On the other hand, UV lamps, such as ultraviolet germicidal lamps, emit primarily ultraviolet light, which is used for sterilization, curing processes, and other applications requiring UV radiation. While CCFLs are designed for light emission in the visible spectrum, UV lamps are specifically designed for UV light generation.” So it seems CCFL converts all or nearly all UV light to visible light, and doesn’t emit much or any UV light – but I couldn’t find anything more concrete than that checking about 5 sources.

I did verify that CCFL lasts somewhere between 20,000 to 40,000 hours and LED 25,000-50,000 hours, one site saying both are about the same at 40,000. Long time, either way!

Luckily I haven’t heard any reports of Triton’s inverter making audible noise, but synths with common 240×64 T6963 LCDs using EL foil backlights/inverters commonly have that issue.

I wonder how the your LED backlit Triton display looks comapred to fresh CCFL. If I wind up changing backlight on a Triton keyboard, I’ll definitely keep in mind that the assembly bracket might be brittle and handle very carefully, thanks!

Finally, re HxC, just be aware that to install on a Gotek, you must still go to HxC “software store” page and right next to where it still says “Ten Euros” click “Buy”; the next page states it’s now free and has you answer simple math problem for verification. It’s a great firmware and creator Jeff/JFDN generously offers outstanding support on forum, etc.

Well, nice job saving a lovely Triton, I’m sure your customer is very happy!

Thnaks again, Connor, and here’s hoping you might engineer and produce both Roland SRX and Triton EXB-PCM wifi adapters soon… 😉

Cheers,

SynD

Thank you SynD, I’ve since added a new plugin on my site for the visitors to be able to subscribe to a e-mail notification for comment of comment…

Regarding parts availability, yes the selection is vast however most are cheap medium to low quality parts. High end parts for niche use are always hard to get here in China, even if you are willing to pay more. Local brands can supply everything but are generally of less quality. Even if some of them know what they are doing, the selection process will be very time consuming.

Alps SKPM usually cannot be used directly, unless the button is 5mm in height and the matching mechanicals can support long travel. It’s also SMT but that can be worked around with some superglue and wires.

CCFL tend to fade over time much faster than LED, the indicated lifetime does not mention brightness loss and only suggests the lamp can still strike and light up. CCFL lifetime is inversely proportional to brightness. With simple setup like the Triton where you cannot adjust brightness (lamp current), I don’t think its lifetime can compare anywhere near properly driven LEDs (50k hours is conservative, usually 100k+ hours can be expected). Another issue for CCFL is extremely bad performance under low temperatures. Here are some references: https://www.analog.com/en/resources/design-notes/ccfl-characteristics.html

where is your location, im really interested

Hi:

I’m located in Beijing, China.